Project Overview

Detailed look at our work with a major aerospace supplier

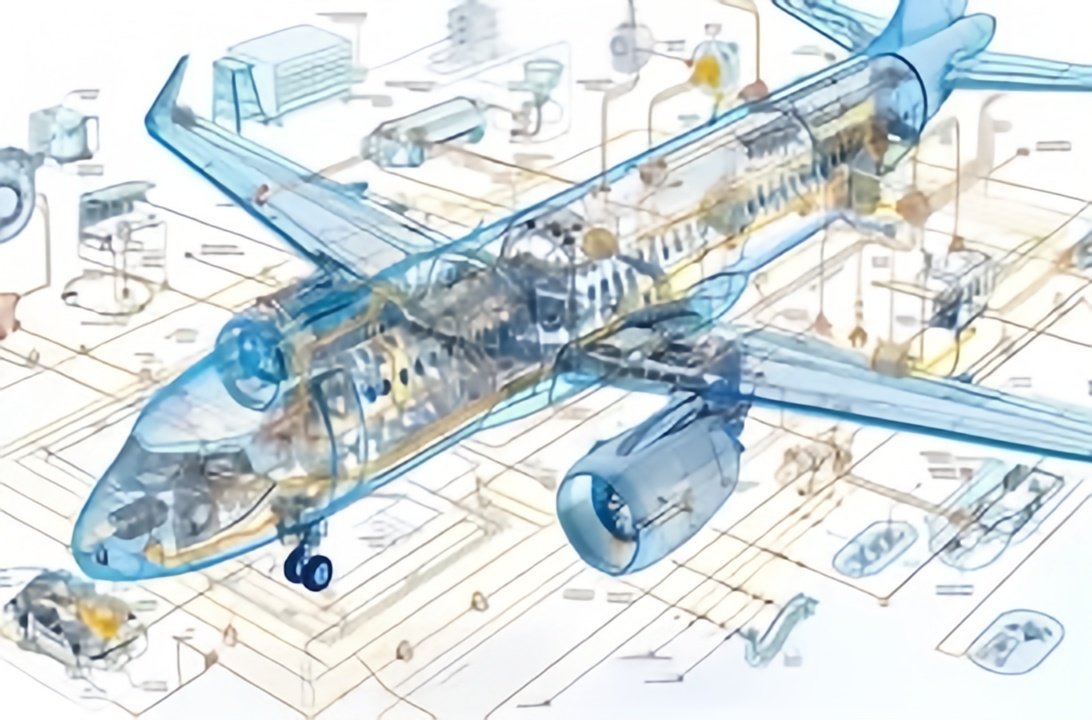

Project Summary

An aerospace supplier required complex fuel system components with extremely tight tolerances and zero-defect quality. These components were critical to the safe operation of aircraft engines and required the highest level of precision and quality control.

Challenge

The aerospace supplier required complex fuel system components with extremely tight tolerances of ±0.002mm. These components were critical to the safe operation of aircraft engines and required zero-defect quality standards.

Additional challenges included:

- Complex internal geometries requiring 5-axis machining

- Specialized aerospace-grade materials that were difficult to machine

- Stringent documentation and traceability requirements

- Strict delivery schedule with no room for delays

Solution

We implemented our AS9100D certified aerospace quality management system and utilized our advanced 5-axis machining centers to produce these critical components.

Our approach included:

- Specialized tooling and custom fixtures designed for the complex geometries

- 100% CMM inspection with detailed reporting for each component

- Full material traceability and documentation compliance

- Dedicated production line to ensure consistent quality

- Regular quality audits throughout the production process

Results

We successfully delivered over 15,000 components with zero defects, exceeding the client's expectations for quality and precision.

Key outcomes:

- 100% quality compliance with zero defects

- On-time delivery for all production runs

- Became approved supplier for 5+ years

- Client reported 20% improvement in their own production efficiency

- Expanded relationship to include additional component types