Our Success Stories

Real-world examples of our precision CNC machining solutions

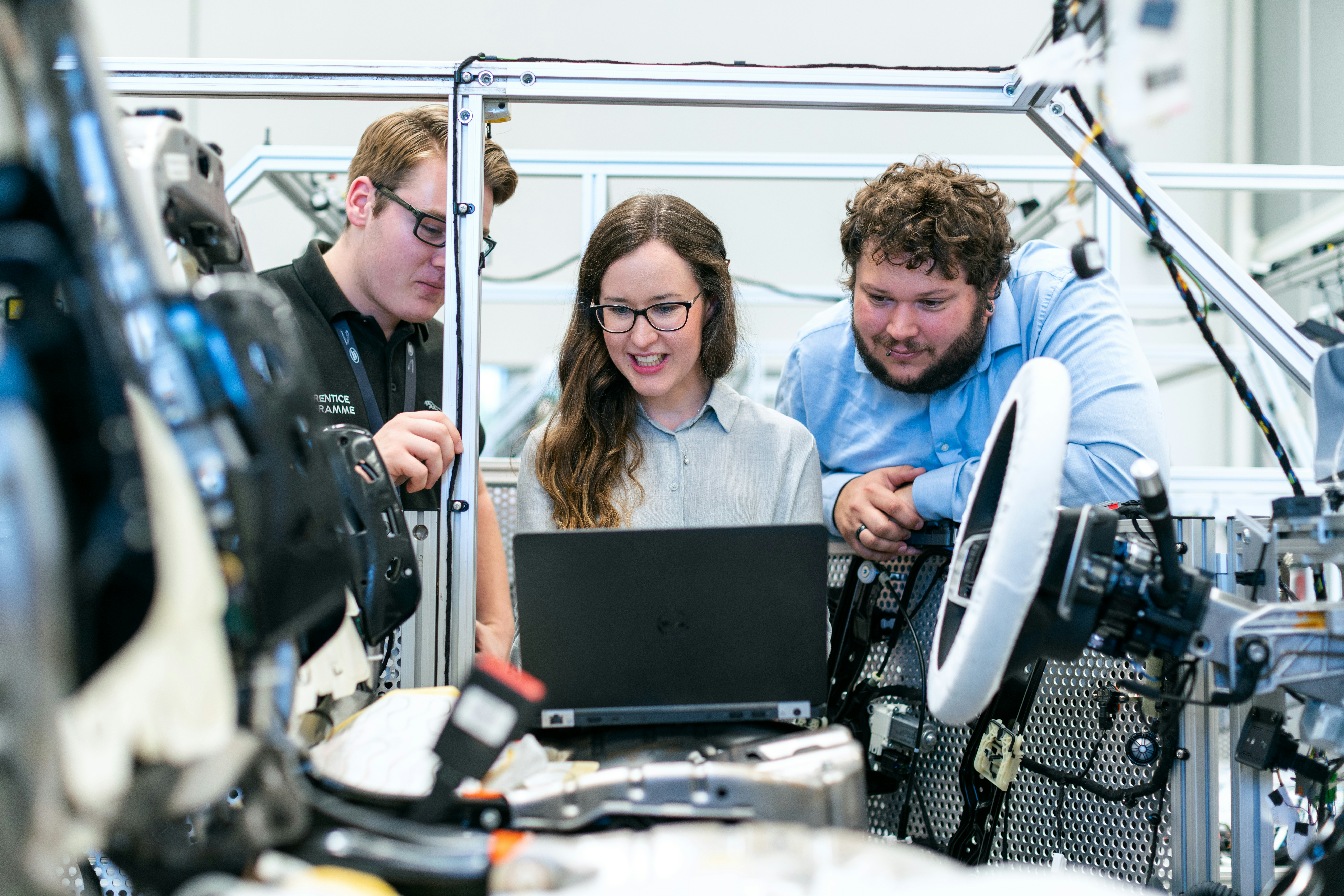

Automotive Engine Component

Challenge

Global TOP3 automotive brand required complex engine components with tight tolerances and challenging material (Inconel 718).

Solution

Utilized our 5-axis machining centers with specialized tooling and custom fixtures to achieve required precision.

Results

Delivered 10,000+ parts with 99.97% quality compliance and 20% faster delivery than competition.

Medical Implant Device

Challenge

Medical device manufacturer needed implant components with biocompatible titanium alloy and ultra-precision surface finish.

Solution

Implemented ISO 13485 compliant processes with specialized cleaning and quality inspection protocols.

Results

Achieved Ra 0.2μm surface finish and 100% quality compliance for 5000+ components.

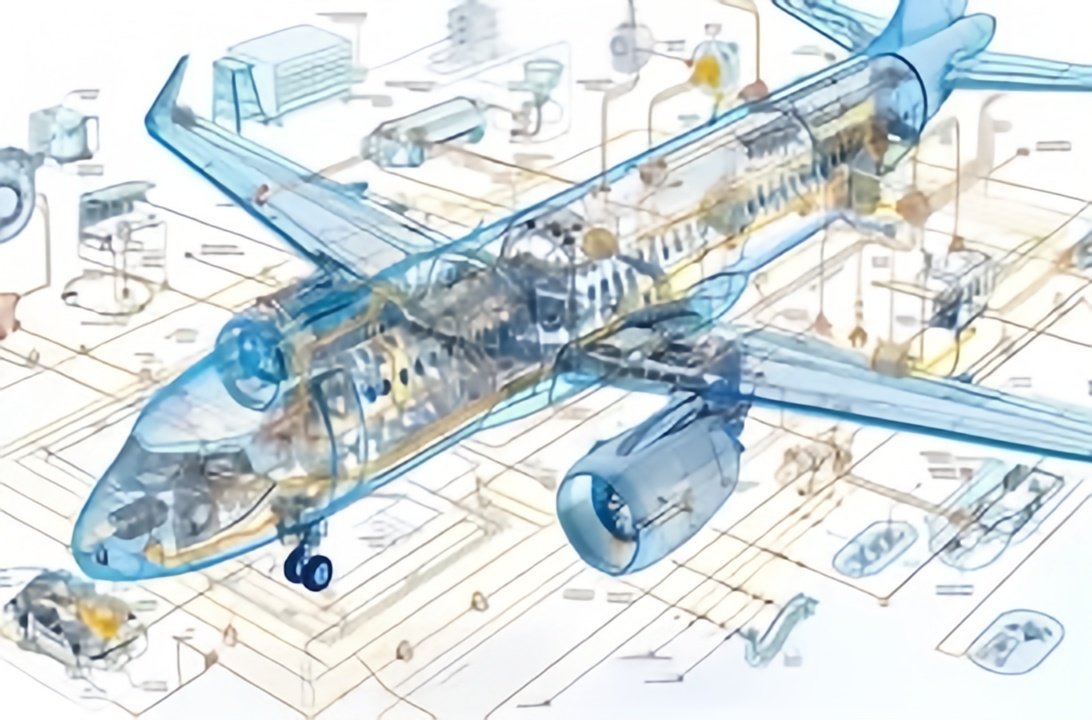

Aerospace Fuel System Component

Challenge

Aerospace supplier required complex fuel system components with extremely tight tolerances and zero-defect quality.

Solution

Used our AS9100D certified processes with 100% CMM inspection and detailed documentation.

Results

Delivered 15,000+ parts with zero defects and became approved supplier for 5+ years.